The end of the De Minimis era has changed everything for U.S. importers. What used to be a simple process, ship a parcel through a courier, let the carrier auto-clear it, and skip formal documentation, no longer exists. In 2025, every shipment must meet full U.S. customs compliance standards, no matter the value, no matter the carrier.

And in this new reality, the biggest mistake growing brands can make is scaling their import volume without testing their supply chain first.

This is where beta shipments come in, a low-risk, high-reward strategy that lets importers validate their documentation, logistics, compliance, and customs processes before they invest in large-volume imports.

The Need for Testing in the Post-De Minimis Era

For years, U.S. importers relied on couriers and low-value exemptions to move goods cheaply and quickly. But now:

- Couriers no longer auto-clear low-value parcels.

- The De Minimis exception no longer applies.

- CBP expects accurate HS codes, valuation, and country-of-origin declarations for every shipment.

- Incorrect or incomplete documentation leads to holds, penalties, or even cargo refusal.

- And the DOJ/DHS Trade Fraud Task Force has significantly increased enforcement.

This creates a dangerous scenario for importers who continue scaling their operations blindly or assume that carriers will “handle it for them.” Without testing your supply chain under the new rules, every shipment becomes a gamble.

That’s why beta shipments, small, controlled test imports are now essential.

What Exactly Are Beta Shipments?

Beta shipments are low-volume, low-risk trial imports that allow U.S. businesses to validate their compliance and logistics processes before transitioning to full-scale import operations.

Think of it as software beta testing:

- You deploy a controlled test version.

- You measure performance under real operating conditions.

- You identify problems early.

- You fix issues before launching big.

- Assess valuation practices, including preparing for using the First Sale Rule where eligible

A beta shipment is the same idea, except instead of debugging code, you’re testing:

- Documentation

- Valuation

- Customs workflows

- Logistics routing

- Warehouse intake

- ACE entry accuracy

Beta shipments are perfect for testing:

- New SKUs

- New suppliers

- New supply chain routes

- New packaging or labelling formats

- New freight forwarders or 3PLs

They offer minimal financial exposure, low duty outlay, and high learning value, making them the ideal tool for post-De Minimis compliance.

Why Beta Shipments Matter More in 2025

Compliance expectations in 2025 are drastically higher than in years past. Beta shipments matter now because:

- Every shipment requires a formal entry, even single-unit parcels.

- Missing HS codes, vague descriptions, or wrong values are no longer overlooked.

- With the launch of the DOJ/DHS Trade Fraud Task Force, CBP is now deeply focused on undervaluation, vague product descriptions, misclassification, and origin fraud.

- Carriers and 3PLs require pre-clearance documentation before they move cargo.

- Couriers can no longer absorb compliance errors or act as a “shield.”

- The DOJ/DHS Trade Fraud Task Force has increased investigations into valuation and misclassification.

In this environment, beta shipments act as early warning systems, helping importers identify issues before they become costly disruptions.

What Beta Shipments Reveal About Your Supply Chain

When performed correctly, beta shipments test every essential component of your import operations.

1. Documentation Quality

Beta shipments expose weak documentation, including:

- Inaccurate or vague commercial invoices

- Missing or incorrect country of origin

- Poor supplier consistency

- Mismatched product descriptions

- Incomplete tariff classification

- Missing Incoterms

2. HS Code Accuracy

Incorrect classifications cause:

- Wrong duty rates

- PGA review delays

- Audit triggers

- Valuation discrepancies

A beta shipment validates your HS codes before importing in large volumes. Use reference workflows from our Quick Start Guide to Stress-Free Importing.

3. Valuation Practices

Beta shipments help confirm:

- Correct declared value

- Acceptable discounts

- Whether the First Sale Rule may be used for duty reduction

Perfect for importers building long-term cost structures.

4. PGA Requirements

If your goods fall under:

- FDA

- USDA

- CPSC

- EPA

Beta shipments reveal regulatory obligations before volume increases.

5. Logistics Coordination

They test how well your partners work together:

- Carrier → broker → warehouse → 3PL

- Routing accuracy

- Labeling compatibility

- Warehouse intake times

You can identify weak links early.

6. ACE Entry Readiness

Errors in ACE entries typically come from:

- Mismatched supplier data

- Inconsistent invoice formats

- Missing classification details

Beta shipments confirm whether your data flows correctly into CBP systems.

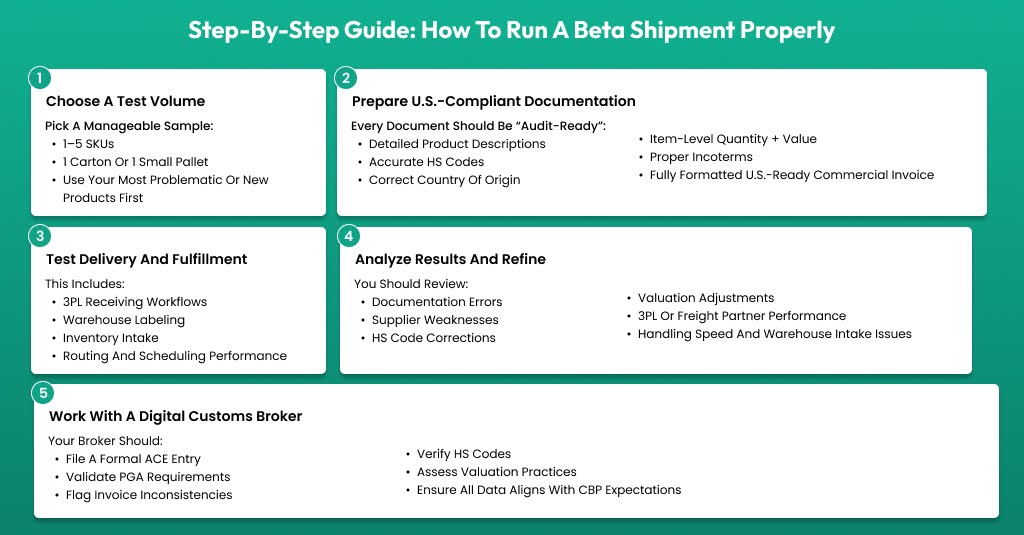

Step-by-Step Guide: How to Run a Beta Shipment Properly

Follow this five-step framework to get the most value from a beta shipment:

Step 1: Choose a Test Volume

Pick a manageable sample:

- 1–5 SKUs

- 1 carton or 1 small pallet

- Use your most problematic or new products first

Step 2: Prepare U.S.-Compliant Documentation

Every document should be “audit-ready”:

- Detailed product descriptions

- Accurate HS codes

- Correct country of origin

- Item-level quantity + value

- Proper Incoterms

- Fully formatted U.S.-ready commercial invoice

Step 3: Work with a Digital Customs Broker

Your broker should:

- File a formal ACE entry

- Validate PGA requirements

- Flag invoice inconsistencies

- Verify HS codes

- Assess valuation practices

- Ensure all data aligns with CBP expectations

Step 4: Test Delivery and Fulfillment

This includes:

- 3PL receiving workflows

- Warehouse labeling

- Inventory intake

- Routing and scheduling performance

This ensures your post-clearance logistics are fully functional.

Step 5: Analyze Results and Refine

You should review:

- Documentation errors

- Supplier weaknesses

- HS code corrections

- Valuation adjustments

- 3PL or freight partner performance

- Handling speed and warehouse intake issues

Once refined, you’re ready for bulk shipments.

Real Benefits: How Beta Shipments Reduce Risk

Beta shipments significantly reduce financial, compliance, and operational risk.

They help importers:

- Prevent widespread shipment holds

- Identify suppliers who mislabel, misclassify, or undervalue goods

- Correct valuation practices before audits

- Detect missing PGA requirements

- Minimize duty errors

- Verify HS code accuracy

- Reduce risk of carrier refusal

- Strengthen supply chain predictability

- Correct entries increase eligibility for programs like IEEPA/USMCA refund opportunities.

- Ensure readiness for full-scale freight importing

Conclusion

Post-De Minimis importing is no longer simple. It requires:

- Structured compliance

- Accurate documentation

- Tested logistics workflows

- Coordinated supply chain partners

- Correct classification and valuation

- Reliable ACE entry processes

Beta shipments offer importers a risk-free, cost-effective, and practical way to validate their supply chain before scaling into full freight operations.

Before you scale, test. Beta shipments help you build a compliant, efficient import model without the risk.

FAQs

Do beta shipments require a formal customs entry?

Yes. Every shipment in 2025 requires a formal entry, even beta shipments.

How small can a beta shipment be?

As small as one SKU, one carton, or one pallet, whatever best tests your process.

Can I use couriers for beta shipments?

You can, but couriers provide no compliance protection. Treat them as formal entries.

Do beta shipments help with audit preparedness?

Absolutely. They reveal documentation, classification, and valuation issues early.

How many beta shipments should I run before scaling?

Most importers run 1–3 shipments to refine processes, depending on the number of SKUs and suppliers.